Hōʻike Kaʻina Hana/Lako

Lapaʻau ʻili

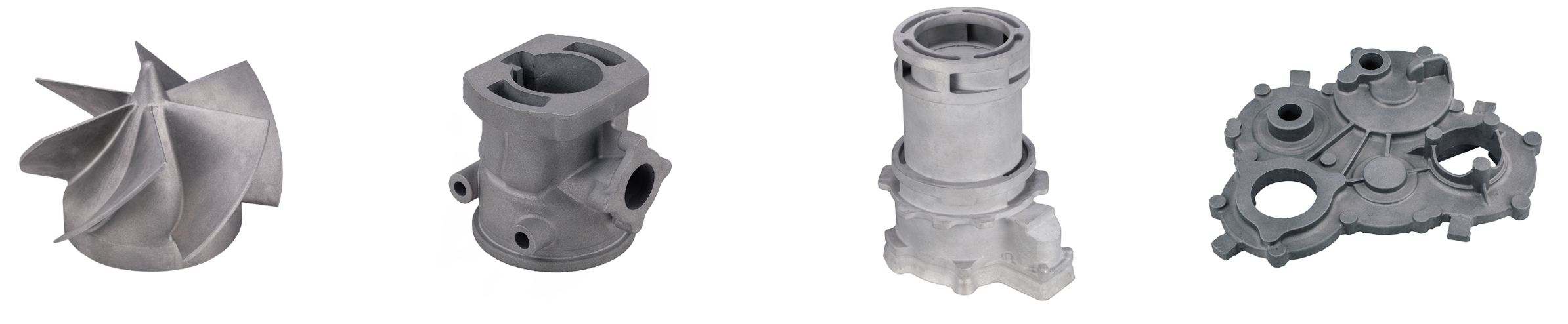

ʻO ka hoʻomaʻamaʻa ʻili ʻana he kaʻina hana no ka hoʻokumu ʻana i kahi papa ʻili ma luna o ka ʻili o ka mea substrate i ʻokoʻa mai nā ʻano mīkini, kino a me nā mea kemika o ka substrate.ʻO ke kumu o ka mālama ʻana i ka ʻili e hoʻokō i ke kūpaʻa corrosion, ke kūpaʻa ʻaʻahu, ka hoʻonaninani a i ʻole nā koi hana kūikawā ʻē aʻe o ka huahana.No ka metala castings, mākou oi maʻamau hoʻohana 'ilikai lapaau 'ano he mechanical polishing, kemika lapaau, ili wela lapaʻau, e pulupulu i ka ili, ili lapaau mea e hoʻomaʻemaʻe, hoʻomaʻemaʻe, deburring, degreasing, deoxide, etc. ma luna o ka ili o ka workpiece.

Electrolysis

ʻO ka Electrolysis kahi kaʻina hana e hoʻokō ʻia ai ka synthesis kemika o nā mea maʻemaʻe kiʻekiʻe a me ka mālama ʻana i ka ʻili o ka honua e nā hopena electrochemical e kū nei ma ke kikowaena ma waena o kahi electrode ma ke ʻano he conductor uila a me ka electrolyte ma ke ʻano he conductor ion.

ʻO ka hoʻopololei

ʻO ka polishing e pili ana i ka hoʻohana ʻana i ka hana mechanical, chemical a electrochemical paha e hōʻemi i ka ʻili o ka ʻili o ka mea hana no ka loaʻa ʻana o kahi ʻano hana hoʻonaninani a palahalaha.ʻO ia ka hoʻohana ʻana i nā mea hana polishing a me nā ʻāpana abrasive a i ʻole nā mea hoʻonaninani ʻē aʻe e hoʻololi i ka ʻili o ka mea hana.

ʻO ka hoʻoheheʻe ʻana

Hoʻohana ke kaʻina hana sandblasting i ka ea i hoʻopili ʻia e like me ka mana e hana ai i kahi kukuna jet kiʻekiʻe, a hoʻopuʻi i ka mea hoʻoheheʻe ʻia i ka ʻili o ka mea hana e hana ʻia i kahi wikiwiki kiʻekiʻe, no laila e loli ke ʻano o ka ʻili o waho o ka mea hana.Ma muli o ka hopena a me ka ʻoki ʻana o ka mea abrasive ma luna o ka ʻili o ka mea hana, ka ʻili o ka mea hana E loaʻa i kahi pae o ka maʻemaʻe a me nā ʻano ʻokoʻa like ʻole, i hoʻomaikaʻi ʻia nā ʻano mechanical o ka ʻili hana.

ʻOke ʻana

ʻO ka oxidation e pili ana i ka hiki o kahi mea ke loaʻa nā electrons.ʻO nā mea i loko o ke kūlana valence kiʻekiʻe a me nā mea metala ikaika ʻole (e like me ka fluorine, chlorine, oxygen, a me nā mea ʻē aʻe).ʻO ka hoʻomaʻamaʻa oxidation o nā metala, ʻo ia ka pilina o ka ʻili metala me ka oxygen a i ʻole oxidant e hana i kahi kiʻi ʻoniʻoni pale e pale ai i ka ʻino metala.

Electroplating

ʻO ka Electroplating kahi lapaʻau ʻili metala e pili ana i ka uhi ʻana i kahi ʻāpana lahilahi o kekahi metala a i ʻole nā mea hao ma kahi ʻāpana metala e pale aku ai i ka ʻinoʻino a me ka oxidation o ka mea hana, a i ʻole e hoʻololi i kona helehelena.ʻO Tin, nickel, zinc (galvanized) a me chromium nā metala electroplating maʻamau, ʻoiai ke keleawe a me ke kila kalapona nā metala maʻamau ʻelua e hoʻohana ana i nā kaʻina hana electroplating.

Kalai Laser

ʻO ke kahakaha ʻana i ka laser e hana i nā hōʻailona pololei a mau loa ma nā metala a me kekahi mau plastic.

Ke ʻala ʻana

Hiki i ka wili lima ke wehe i nā māka mīkini, hoʻopau i nā burrs ma ka ʻili o nā ʻāpana, nā laina hana a me nā hōʻailona adhesion a me nā hemahema huahana ʻē aʻe.E hoʻomaikaʻi ʻia ka palahalaha o nā ʻāpana a e hoʻemi ʻia ka ʻōpala no ka loaʻa ʻana o ka helehelena maʻemaʻe a kūlike.

Māhele huahana

-

wechat

-

Whatsapp

whatsapp