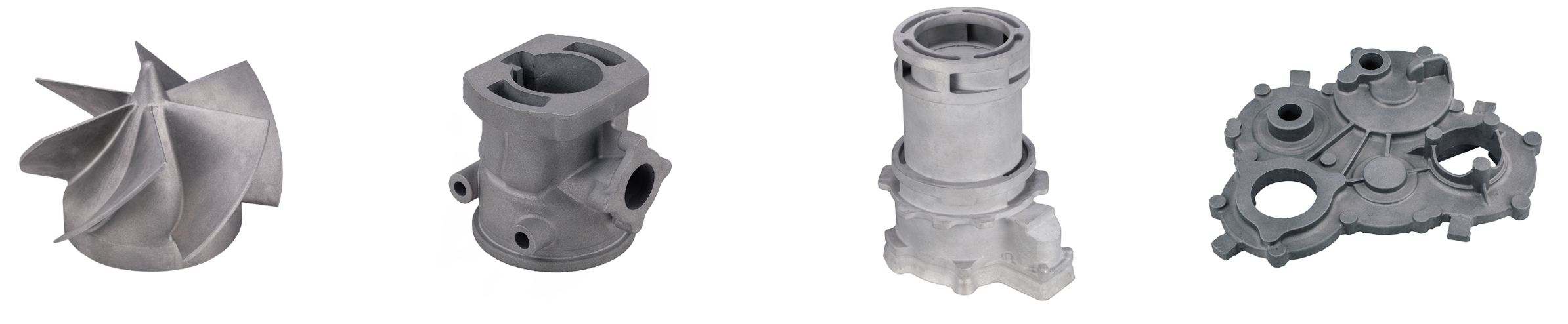

Cov txheej txheem / khoom siv zaub

Kev kho saum npoo

Kev kho deg yog txheej txheem ntawm kev tsim cov txheej txheem saum npoo ntawm cov khoom siv substrate uas txawv ntawm cov khoom siv kho tshuab, lub cev thiab tshuaj lom neeg ntawm lub substrate.Lub hom phiaj ntawm kev kho saum npoo yog ua kom tau raws li qhov kev tiv thaiv corrosion, hnav tsis kam, kho kom zoo nkauj lossis lwm yam kev ua haujlwm tshwj xeeb ntawm cov khoom.Rau cov hlau castings, peb feem ntau siv cov txheej txheem kho saum npoo yog cov tshuab polishing, tshuaj kho, kho cua sov, tshuaj tsuag qhov chaw, kev kho deg yog ntxuav, ntxuav, deburring, degreasing, deoxide, thiab lwm yam.

Electrolysis

Electrolysis yog txheej txheem uas cov tshuaj synthesis ntawm high-purity tshuaj thiab cov khoom nto kho yog nqa tawm los ntawm electrochemical tshuaj tshwm sim nyob rau hauv lub interface ntawm ib tug electrode raws li ib tug hluav taws xob conductor thiab ib tug electrolyte raws li ib tug ion conductor.

Polishing

Polishing yog hais txog kev siv tshuab, tshuaj lom neeg lossis electrochemical ua kom txo tau qhov roughness ntawm cov khoom ua haujlwm kom tau txais txoj kev ua haujlwm ci thiab tiaj tus.Nws yog siv cov cuab yeej polishing thiab abrasive hais los yog lwm yam xov xwm polishing los hloov kho qhov chaw ntawm lub workpiece.

Sandblasting

Cov txheej txheem sandblasting siv cov cua compressed raws li lub zog los tsim lub dav hlau dav hlau nrawm, thiab txau cov khoom siv tshuaj tsuag rau saum npoo ntawm lub workpiece kom ua tiav ntawm kev kub ceev, yog li ntawd cov tsos ntawm sab nrauv ntawm lub workpiece hloov.Vim muaj kev cuam tshuam thiab txiav cov nyhuv ntawm abrasive rau ntawm qhov chaw ntawm lub workpiece, qhov saum npoo ntawm lub workpiece tau txais qee qhov kev huv huv thiab qhov sib txawv ntawm qhov sib txawv, kom cov khoom siv ntawm lub workpiece nto zoo tuaj.

Oxidation

Oxidation yog hais txog lub peev xwm ntawm ib yam khoom kom tau txais electrons.Cov tshuaj nyob rau hauv lub xeev siab valence thiab cov khoom tsis yog xim hlau (xws li fluorine, chlorine, oxygen, thiab lwm yam) feem ntau yog oxidizing.Kev kho oxidation ntawm cov hlau yog kev sib cuam tshuam ntawm cov hlau nto nrog cov pa oxygen lossis oxidant los tsim cov yeeb yaj kiab oxide tiv thaiv kom tsis txhob xeb hlau.

Electroplating

Electroplating yog txheej txheej hlau uas muaj txheej txheej nyias nyias ntawm lwm cov hlau lossis hlau alloy ntawm cov hlau los tiv thaiv corrosion thiab oxidation ntawm lub workpiece, los yog hloov nws cov tsos.Tin, npib tsib xee, zinc (galvanized) thiab chromium yog txhua yam electroplating hlau, thaum tooj liab thiab carbon hlau yog ob hom hlau uas siv cov txheej txheem electroplating.

Laser Carving

Laser engraving yog ua kom meej thiab ruaj khov rau cov hlau thiab qee yam yas.

Sanding

Kev sib tsoo los ntawm txhais tes tuaj yeem tshem tawm cov cim machining, tshem tawm cov burrs ntawm qhov chaw, cov kab ntau lawm thiab cov cim adhesion thiab lwm yam khoom tsis xws luag.Lub flatness ntawm cov khoom yuav raug txhim kho thiab cov roughness yuav raug txo kom ua tiav qhov zoo nkauj thiab zoo ib yam.

Cov khoom qeb

-

wechat

-

Whatsapp

whatsapp