Ngosipụta usoro/ngwaọrụ

Ọgwụgwọ elu

Ngwọta dị n'elu bụ usoro nke ịmepụta oyi akwa dị elu n'elu ihe nke dị iche na ihe eji arụ ọrụ, anụ ahụ na kemịkal nke mkpụrụ ahụ.Ebumnuche nke ọgwụgwọ elu bụ izute nguzogide corrosion, iyi nguzogide, ịchọ mma ma ọ bụ ihe ndị ọzọ chọrọ ọrụ pụrụ iche nke ngwaahịa ahụ.N'ihi na metal nkedo, anyị na-ejikarị n'elu ọgwụgwọ ụzọ bụ n'ibu polishing, chemical ọgwụgwọ, elu okpomọkụ ọgwụgwọ, spraying n'elu, elu ọgwụgwọ bụ ọcha, ọcha, deburring, degreasing, deoxide, wdg n'elu nke workpiece.

Electrolysis

Electrolysis bụ usoro nke njikọ kemịkalụ nke ihe dị oke ọcha na ọgwụgwọ elu ihe na-eme site na mmeghachi omume electrochemical na-eme na interface n'etiti electrode dị ka onye na-eduzi eletrọnịkị na electrolyte dị ka onye na-eduzi ion.

Nchacha

Polishing na-ezo aka n'iji igwe, kemịkalụ ma ọ bụ electrochemical eme ihe iji belata nhụsianya elu nke workpiece iji nweta usoro nhazi elu na-egbuke egbuke ma dị larịị.Ọ bụ ojiji nke polishing ngwaọrụ na abrasive ahụ ma ọ bụ ndị ọzọ polishing media gbanwee elu nke workpiece.

Ịgba aja

The sandblasting usoro na-eji abịakọrọ ikuku dị ka ike na-etolite a elu-ọsọ jet doo, na sprays na ịgba ihe n'elu nke workpiece na-esichara na a nnukwu ọsọ, nke mere na ọdịdị nke elu elu nke workpiece mgbanwe.N'ihi mmetụta na mbelata mmetụta nke abrasive n'elu nke workpiece, elu nke workpiece nweta a ụfọdụ ogo nke ịdị ọcha na dị iche iche roughness, nke mere na n'ibu Njirimara nke workpiece elu na-mma.

Oxidation

Oxidation na-ezo aka n'ikike nke ihe iji nweta electrons.Ihe ndị dị na steeti valence dị elu na ihe ndị na-adịghị arụ ọrụ (dị ka fluorine, chlorine, oxygen, wdg) na-emekarị oxidizing.Usoro ọgwụgwọ oxidation nke ọla bụ mmekọrịta nke elu igwe na ikuku oxygen ma ọ bụ oxidant iji mepụta ihe nkiri oxide na-echebe iji gbochie mmebi ígwè.

Electrorating

Electroplating bụ a metal elu ọgwụgwọ na-agụnye ikpuchi a dị gịrịgịrị oyi akwa nke ọzọ metal ma ọ bụ metal alloy na metal akụkụ iji gbochie corrosion na oxidation nke workpiece, ma ọ bụ ịgbanwe ọdịdị ya.Tin, nickel, zinc (galvanized) na chromium bụ ọla electroplating niile, ebe ọla kọpa na carbon steel bụ ọla abụọ a na-ahụkarị na-eji usoro electroplating.

Ọkpụkpụ Laser

Ihe osise laser bụ ime akara ziri ezi na nke na-adịgide adịgide na ọla na ụfọdụ plastik.

Ịgba aja

Iji aka na-egweri nwere ike wepụ akara machining, wepụ burrs n'elu akụkụ, mmepụta ahịrị na adhesion akara na ndị ọzọ ngwaahịa ntụpọ.A ga-eme ka ihe dị larịị nke akụkụ ahụ dịkwuo mma, a ga-ebelata ịdị njọ iji nweta ọdịdị dị mma na nke na-agbanwe agbanwe.

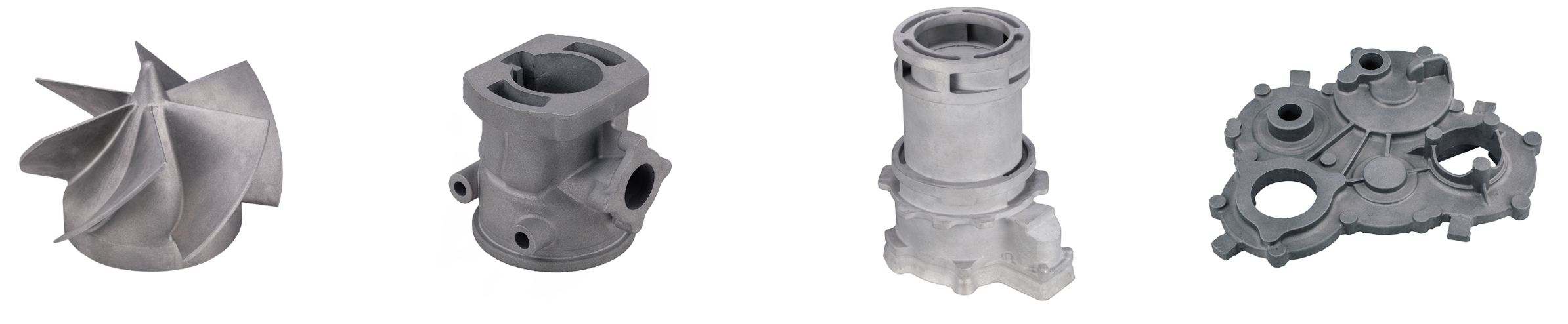

Ụdị ngwaahịa

-

wechat

-

WhatsApp

whatsapp