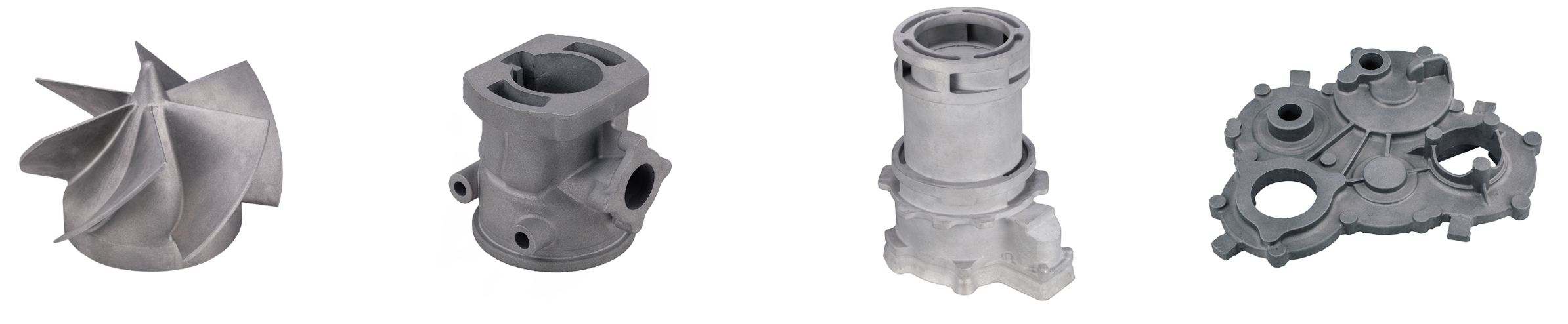

Pontšo ea Ts'ebetso / Thepa

Kalafo ea Bokaholimo

Phekolo ea ka holim'a metsi ke mokhoa oa ho etsa lera le ka holimo holim'a thepa ea substrate e fapaneng le ea mechine, ea 'mele le ea lik'hemik'hale ea substrate.Sepheo sa phekolo ea holim'a metsi ke ho finyella ho hanyetsa ha kutu, ho hanyetsa ho roala, mokhabiso kapa litlhoko tse ling tse khethehileng tsa ts'ebetso ea sehlahisoa.Bakeng sa li-castings tsa tšepe, re atisa ho sebelisoa mekhoa ea phekolo ea holim'a metsi ke ho bentša ka mochine, phekolo ea lik'hemik'hale, phekolo ea mocheso oa holim'a metsi, ho fafatsa ka holim'a metsi, phekolo ea holim'a metsi ke ho hloekisa, ho hloekisa, ho senya, ho senya, deoxide, joalo-joalo holim'a workpiece.

Electrolysis

Electrolysis ke ts'ebetso eo ho eona motsoako oa lik'hemik'hale oa lintho tse hloekileng haholo le kalafo ea holim'a lintho tse bonahalang li etsoang ke karabelo ea electrochemical e hlahang sebopehong lipakeng tsa eleketrode joalo ka mokhanni oa elektroniki le electrolyte joalo ka mokhanni oa ion.

Ho benya

Ho pholisa ho bolela ts'ebeliso ea ts'ebetso ea mochini, ea lik'hemik'hale kapa ea electrochemical ho fokotsa bokhabane ba bokaholimo ba mosebetsi ho fumana mokhoa o khanyang le o bataletseng oa ho sebetsa holim'a metsi.Ke tšebeliso ea lisebelisoa tsa polishing le likaroloana tsa abrasive kapa mecha e meng ea ho bentša ho fetola bokaholimo ba mosebetsi.

Ho qhomisa lehlabathe

Ts'ebetso ea sandblasting e sebelisa moea o hatelitsoeng e le matla a ho etsa sefate sa jete se phahameng ka lebelo, 'me se fafatsa thepa ea spray holim'a sebaka sa mosebetsi se lokelang ho sebetsoa ka lebelo le phahameng, e le hore ponahalo ea ka ntle ea workpiece e fetohe.Ka lebaka la tšusumetso le phello ea ho itšeha ea abrasive holim'a workpiece, holim'a workpiece Fumana tekanyo e itseng ea bohloeki le mefuta e fapaneng ea mahlahahlaha, e le hore thepa ea mechine ea sebaka sa workpiece e ntlafatsoe.

Oxidation

Oxidation e bolela bokhoni ba ntho ea ho fumana lielektrone.Lintho tse maemong a phahameng a valence le likarolo tse sebetsang tse seng tsa tšepe (joalo ka fluorine, chlorine, oxygen, joalo-joalo) hangata li etsa oxidizing.Phekolo ea oxidation ea tšepe ke ho sebelisana ha bokaholimo ba tšepe le oksijene kapa oxidant ho theha filimi e sireletsang ea oxide ho thibela kutu ea tšepe.

Electroplating

Electroplating ke phekolo ea holim'a tšepe e kenyelletsang ho roala lesela le tšesaane haholo la tšepe e 'ngoe kapa tšepe e kopantsoeng karolong ea tšepe ho thibela ho bola le oxidation ea workpiece, kapa ho fetola ponahalo ea eona.Tin, nickel, zinki (galvanized) le chromium kaofela ke litšepe tse tloaelehileng tsa electroplating, athe koporo le carbon steel ke litšepe tse peli tse tloaelehileng tse sebelisang mekhoa ea electroplating.

Ho betla ka Laser

Laser engraving ke ho etsa matšoao a nepahetseng le a sa feleng holim'a litšepe le lipolasetiki tse itseng.

Ho hlaba lehlabathe

Ho sila ka letsoho ho ka tlosa matšoao a machining, ho felisa li-burrs holim'a likarolo, mela ea tlhahiso le matšoao a ho khomarela le liphoso tse ling tsa sehlahisoa.Bophahamo ba likarolo bo tla ntlafatsoa 'me bokhopo bo fokotsehe ho finyella ponahalo e boreleli le e tsitsitseng.

Lihlopha tsa lihlahisoa

-

wechat

-

Whatsapp

whatsapp