Burrs on parts are very dangerous: first, it will increase the risk of personal injury; Secondly, in the downstream processing process, it will endanger the product quality, affect the use of equipment and even shorten the service life of equipment. In this article, we will introduce how to use advanced deburring equipment to remove burrs, help you reduce production costs and improve processing efficiency.

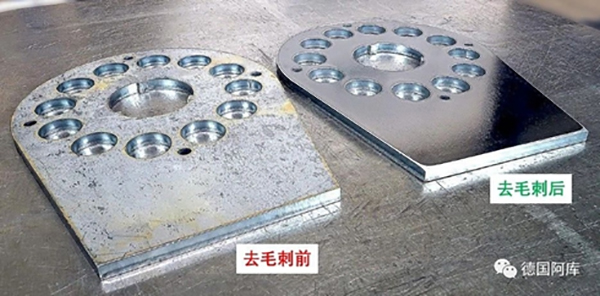

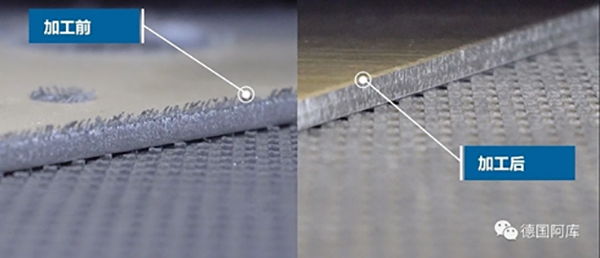

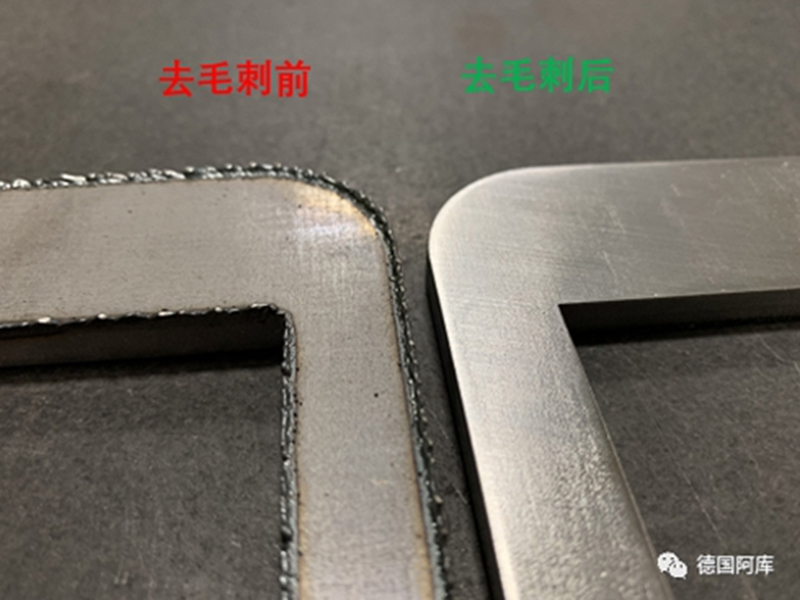

Whether punching, laser cutting or plasma cutting, these machining processes will form sharp edges and burrs on the surface of parts. Especially during plasma cutting, slag (mixture of oxides and metal residues) will be stubborn deposited on the edge of the part. No matter which cutting method is adopted, it is very important to deburr various parts after cutting. The reasons are as follows:

1. Deburring can reduce the risk of injury

Sharp edges and burrs are very dangerous, and workers are easy to scratch during operation, which will affect the smooth progress of work in serious cases. On the one hand, adding deburring and rounding process can improve the safety of the working environment and reduce the downtime cost; On the other hand, it can ensure the safety of personnel in all processes of the production chain, and the risk of personal injury is almost zero.

2. Deburring can improve product quality

Burrs are not only dangerous to people, but also to tools and machines. For example, the bending machine or roller leveler, if the parts of these machines often contact the sharp edges and burrs on the machined parts, the wear will become faster, and the serious cases will directly lead to the production stop and cannot be used. Therefore, deburring and rounding of parts is an important condition to protect tools and machines, extend their service life and reduce maintenance costs.

3. Manual deburring has reached the economic benefit limit

When deburring machined parts, many enterprises still rely on manual operation. For example, let some experienced workers use a brush or angle grinder to remove edges, burrs and splashes. The advantage of this method is that it can observe whether the surface of the part is damaged or not. It can detect the appearance of the part and make a preliminary judgment while removing the burr. If there is a scratch, it can be picked out, repaired or redone.

Post time: Feb-21-2023