Ukucutshungulwa kwendawo yezingxenyekazi zekhompuyutha kungahlukaniswa kube: ukucutshungulwa kwe-hardware oxidation, ukucutshungulwa kwe-hardware yokudweba, i-electroplating, ukupholisha phezulu, ukugqwala kwehadiwe, njll.

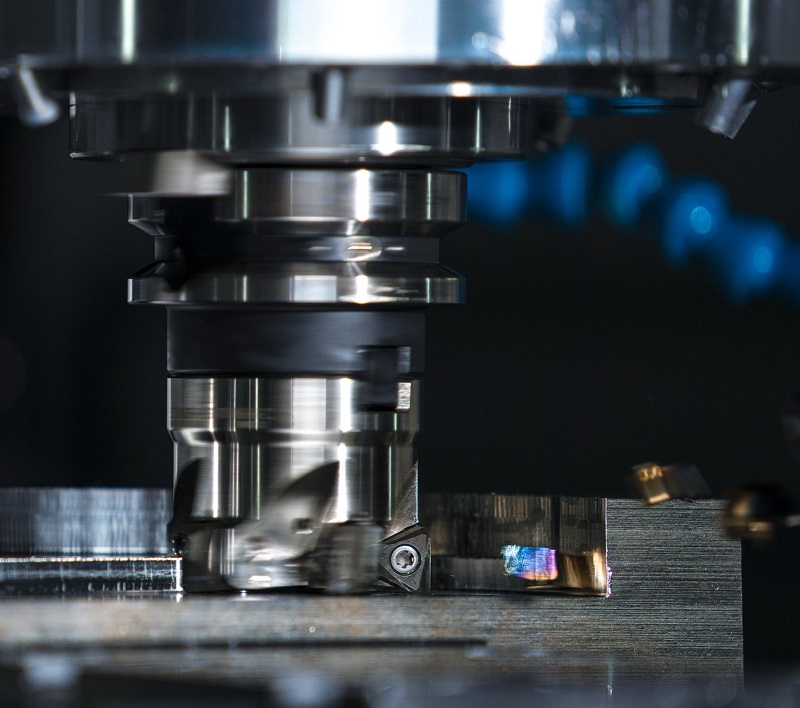

Ukucubungula okungaphezulu kwezingxenye zehadiwe:

1. Ukucutshungulwa kwe-oxidation: imboni yezingxenyekazi zekhompuyutha isebenzisa ukucubungula kwe-oxidation emikhiqizweni ye-hardware eqediwe (ikakhulukazi izingxenye ze-aluminium) ukwenza ingaphezulu lemikhiqizo ye-hardware ibe nzima, Ikwenze kungabi lula ukugqokwa.

2. Ukucubungula ukupenda kwe-spray: ifekthri ye-hardware isebenzisa ukucubungula kwe-spray imidwebo lapho ikhiqiza imikhiqizo emikhulu eqediwe, engavimbela i-hardware ukuthi ingagqwali,Isibonelo: izidingo zansuku zonke, izivalo zikagesi, imisebenzi yezandla, njll.

3. I-Electroplating: I-electroplating ibuye ibe ubuchwepheshe obuvame kakhulu bokucubungula ukucubungula ihadiwe.Ingaphezulu le-hardware li-electroplated ngobuchwepheshe besimanje ukuze kuqinisekiswe ubude bomkhiqizo omude,Asikho isikhutha noma ukubola ngaphansi kokusetshenziswa kwesikhathi.Izinqubo ezivamile ze-electroplating yilezi: izikulufu, izingxenye zokugxiviza, ama-chips ebhethri, izingxenye zemoto, izesekeli ezincane, njll

4. Ukupholishwa kwendawo: ukupholishwa kwendawo ngokuvamile kusetshenziswa ezidingweni zansuku zonke isikhathi eside, futhi ama-burrs angaphezulu emikhiqizo yehadiwe ayaphathwa, njengokuthi:Sikhiqiza ikamu.Ikama yingxenye yensimbi eyenziwe ngokucindezela.Amakhona ekamu elibhontshiwe abukhali kakhulu.Kudingeka ukuthi Imiphetho ebukhali namakhona apholishwe abe ubuso obushelelezi, ukuze kungabikho monakalo ozobangelwa emzimbeni womuntu ngesikhathi sokusetshenziswa.

Indlela yomshini ye-cnc workpiece surface incike ezidingweni zobuchwepheshe zendawo esebenza ngomshini.Kodwa-ke, kufanele kuqashelwe ukuthi lezi zidingo zobuchwepheshe azizona izingxenye

Izidingo ezicaciswe emdwebeni zingase zibe phezulu kunalezo eziyingxenye yomdwebo kwezinye izici ngenxa yezizathu zobuchwepheshe.Uma inyuswa ngenxa yokungaqondani kwedatha

Izidingo zomshini wobuso bezingxenye ezithile zomshini we-cnc.Noma ingase ibeke phambili izidingo zokucubungula eziphezulu ngoba ithathwa njengereferensi enembayo.

Ngemuva kokuthi izidingo zobuchwepheshe zezindawo zezingxenye zomshini we-CNC zicacisiwe, indlela yokugcina yomshini engaqinisekisa izidingo ingakhethwa ngokufanele, kanye nenani lezinyathelo nezindlela zokucubungula zesinyathelo ngasinye.Indlela yokucubungula ekhethiwe yezingxenye zemishini ye-CNC kufanele ihlangabezane nezidingo zekhwalithi yezingxenye, umnotho omuhle wokucubungula kanye nezidingo eziphezulu zokukhiqiza.

Ngenxa yalesi sizathu, izici ezilandelayo kufanele zicatshangelwe lapho kukhethwa indlela yokucubungula:

1. Ukunemba komshini nobulukhuni bendawo etholwe inoma iyiphi indlela yemishini ye-CNC inobubanzi obukhulu, kodwa kuphela kububanzi obuwumngcingo.Ububanzi bayo bungokomnotho, futhi ukunemba komshini kwalobu bubanzi ukunemba komshini wezomnotho.Ngakho-ke, lapho ukhetha indlela yokucubungula, indlela ehambisanayo.Indlela yokucubungula engathola ukunemba kokucubungula kwezomnotho.

2. Izakhiwo ze-CNC machining materials zizocatshangelwa.

3. Ukuma kwesakhiwo nosayizi wezingxenye zomshini we-CNC kuzocatshangelwa.

4. Izidingo zokukhiqiza nezomnotho zizobhekwa.Ukusebenza kahle okuphezulu kanye nobuchwepheshe obuthuthukisiwe buzokwamukelwa ekukhiqizeni ngobuningi.Ingakwazi ngisho nokushintsha okungenalutho.Indlela yokukhiqiza inganciphisa inani lomsebenzi womshini.

5. Impahla ekhona kanye nezimo zobuchwepheshe zefekthri noma indawo yokusebenzela kuyobhekwa.Lapho kukhethwa indlela yokucubungula, okokusebenza okukhona kuzosetshenziswa ngokugcwele ukuzuza amandla ebhizinisi.Intshiseko nobuhlakani babasebenzi.Kodwa-ke, ukuthuthukiswa okuqhubekayo kwezindlela zokucubungula ezikhona kanye nemishini, ukwamukelwa kobuchwepheshe obusha kanye nokwenza ngcono izinga lenqubo nakho kufanele kucatshangelwe.

Isikhathi sokuthumela: Oct-08-2022